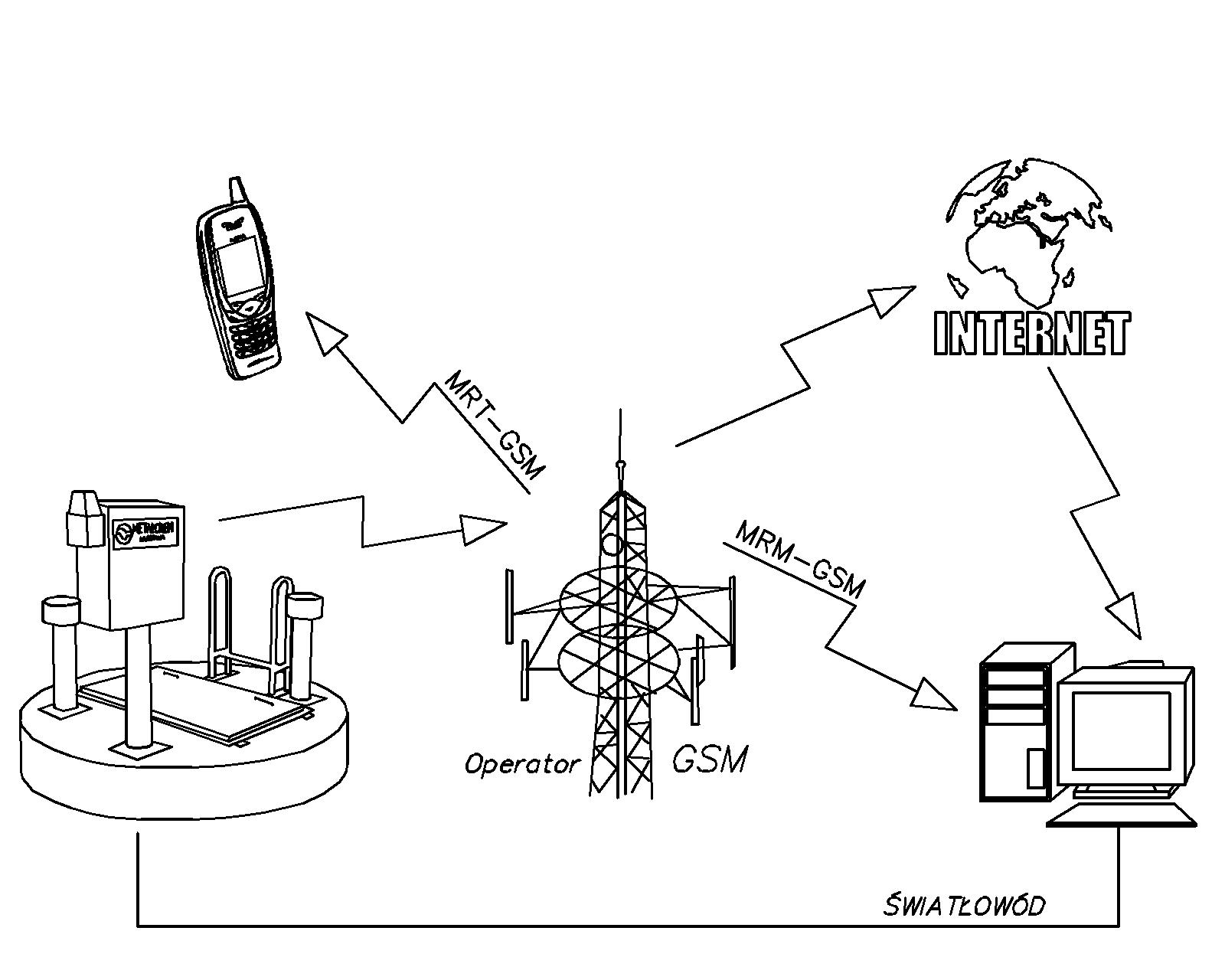

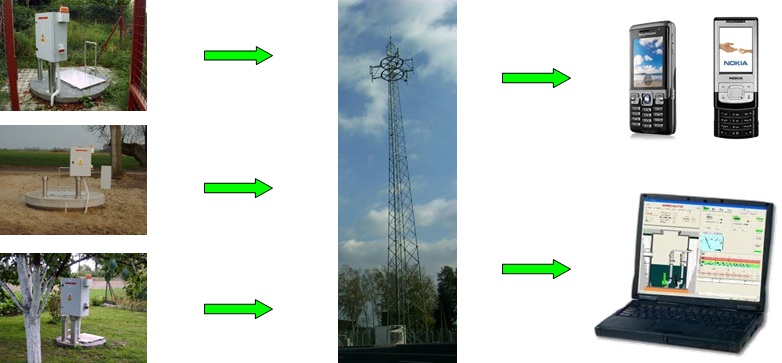

For facilities for which direct supervision is not possible, we offer switchboards with a built-in MRT-GSM or MRM-GPRS wireless monitoring system using a mobile network.

monitoring pumping station is a modern tool for controlling and supervising pumping stations. In addition to observing the ongoing work of the object allows you to prevent major failures and downtime. Based on the work history and changes in the parameters of individual pumping station elements, it is possible to determine e.g. damage or clogging of pumps, failures of floats or controls, uncontrolled sewage discharge or burglary and devastation of the facility. Signals reaching the operator allow him to concentrate his strength and resources on objects requiring immediate service instead of visiting all objects in order to review them. This saves a lot of resources and time while reacting in advance of the failure. Imagine a situation when some objects fail during a heavy downpour or levels in pumping stations are exceeded and threaten to pour wastewater from the tank. An operator supervising several objects at the same time would have to drive from one object to another and check what happens to the pumping stations (sometimes these objects are distant from each other by many kilometers). For example, if the float of the pump start level hangs up, or the pumps get stuck and stop working, the level may rise sewage and flooding the area or property. Penalties for environmental pollution can be very severe, and wastewater removal from the site is not easy and pleasant. In the event of monitoring, the operator would receive a signal that the alarm condition was exceeded in the tank and the pumps were not operating properly. He would know that he must react immediately and operate in this particular pumping station. Of course, it is better to prevent and prevent it than to repair and remove the effects of failure afterwards.

In our offer we distinguish two types of monitoring: unidirectional MRT-GSM based on sms communication and bidirectional MRM-GRPS based on GPRS data transmission. You can read more about the possibilities of monitoring provided by our company in the descriptions of individual types below.

One-way MRT-GSM pumping station monitoring

The simplest control of the pumping station. Emergency messages and their cancellations are sent as SMSes to the indicated mobile phone.

In normal operation mode (no failure), the system establishes communication with the service every 24 hours (communication test – report on pump operation time). In the absence of a message, check the operation of the controller. In the event of an alarm condition, the operator is immediately notified via SMS.

The system has the ability to automatically switch the functions of the microprocessor controller to battery power in the event of a power grid failure (the “Power failure” SMS message is sent and the controller goes into the so-called “sleep” state).

It is possible to block and unblock the controller functions (pumping station operation) from an Android phone (smartphone) dedicated to the Metalchem-Warszawa S.A. program.

Two-way MRM-GPRS pumping station monitoring

advanced pumping station control, which uses GPRS data transmission technology. The pumping station communicates with the dispatching station via a GPRS modem using a cellular network.

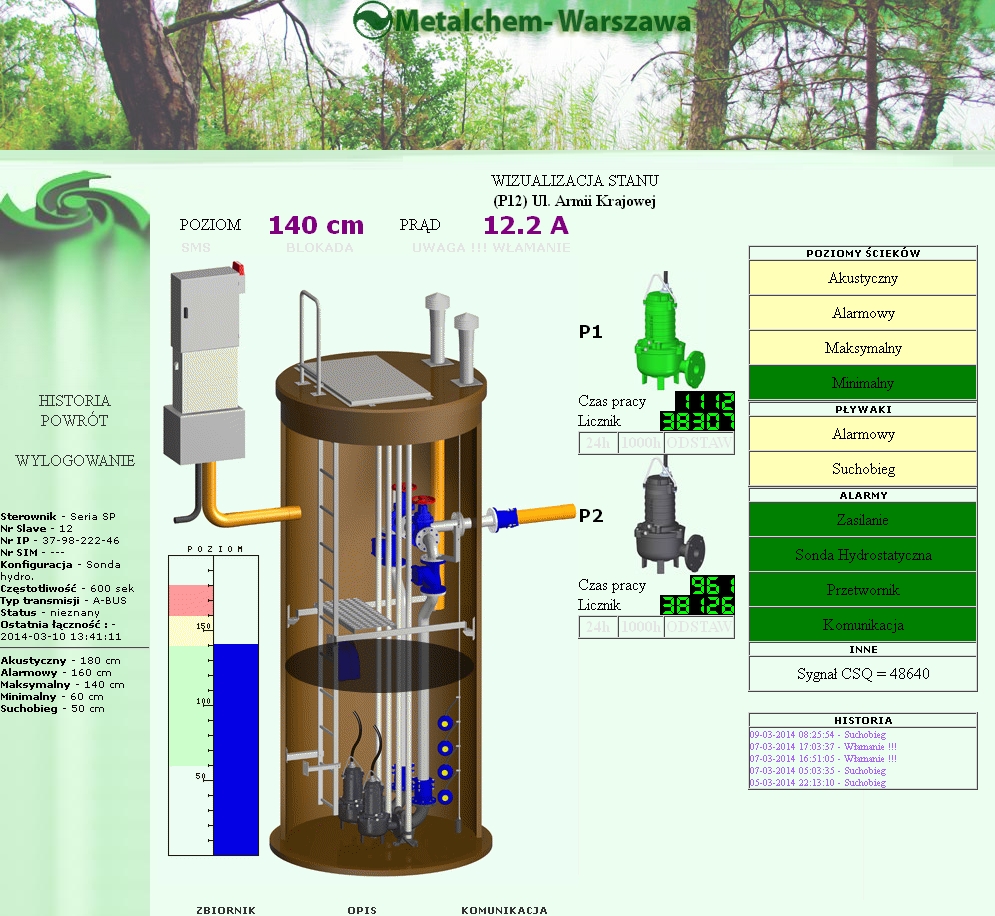

The graphic visualization program of monitored objects enables:

- observation of the current state of the objects,

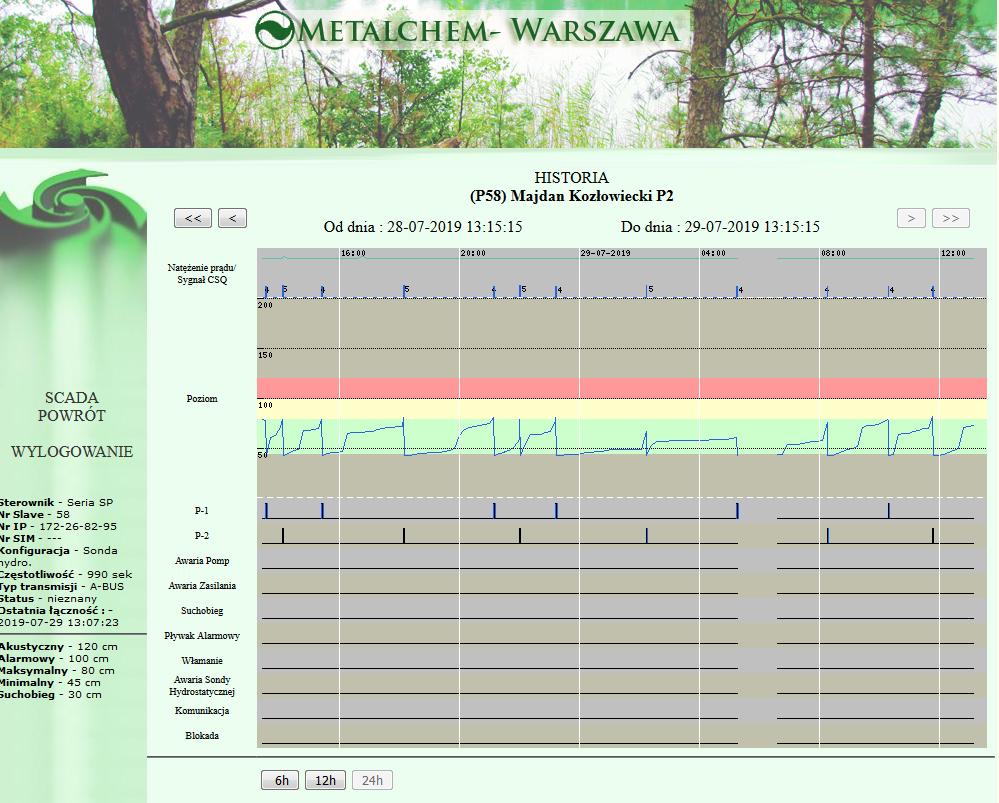

- analysis of pump operation time, failures, (pumps, power supply, communication), current sewage level, communication status, burglary detection (opening the switchboard door) for each facility.

- The user can also view the operation of the pumping station via the internet – a web browser.

Careful analysis of history and individual charts enables prediction the most common failures such as float suspension, failure of the hydrostatic probe, clogged discharge pipe or pump. There are also cases when our monitoring helped detect illegal discharge of sewage to pumping stations or wells sewage systems.

Contact: Krzysztof Moczarski kmoczarski@metalchemsa.pl mob. +48 500 114 195