Systems supporting the work of pumping stations and related facilities

As a leading producer of submersible pumps and sewage pumping stations in Poland, we strive to constantly develop and provide you with solutions that facilitate the daily operation of your facilities. In addition to standard products such as sewage pumps and sewage and rainwater pumping stations, we also provide optional pumping station components. Innovative products include the MASP and MASZ systems developed by us. The first is used for automatic flushing of the pumping station tank during its operation and the second for the remote control of valves in situations where there is no integrated system for managing all devices, such as sewage treatment plants. Both systems have been developed and are still evolving in response to user demand. If your facilities require an unusual approach and solutions that you have not found on the market so far, we invite you to share your ideas with us, maybe soon we will be able to implement such a project together.

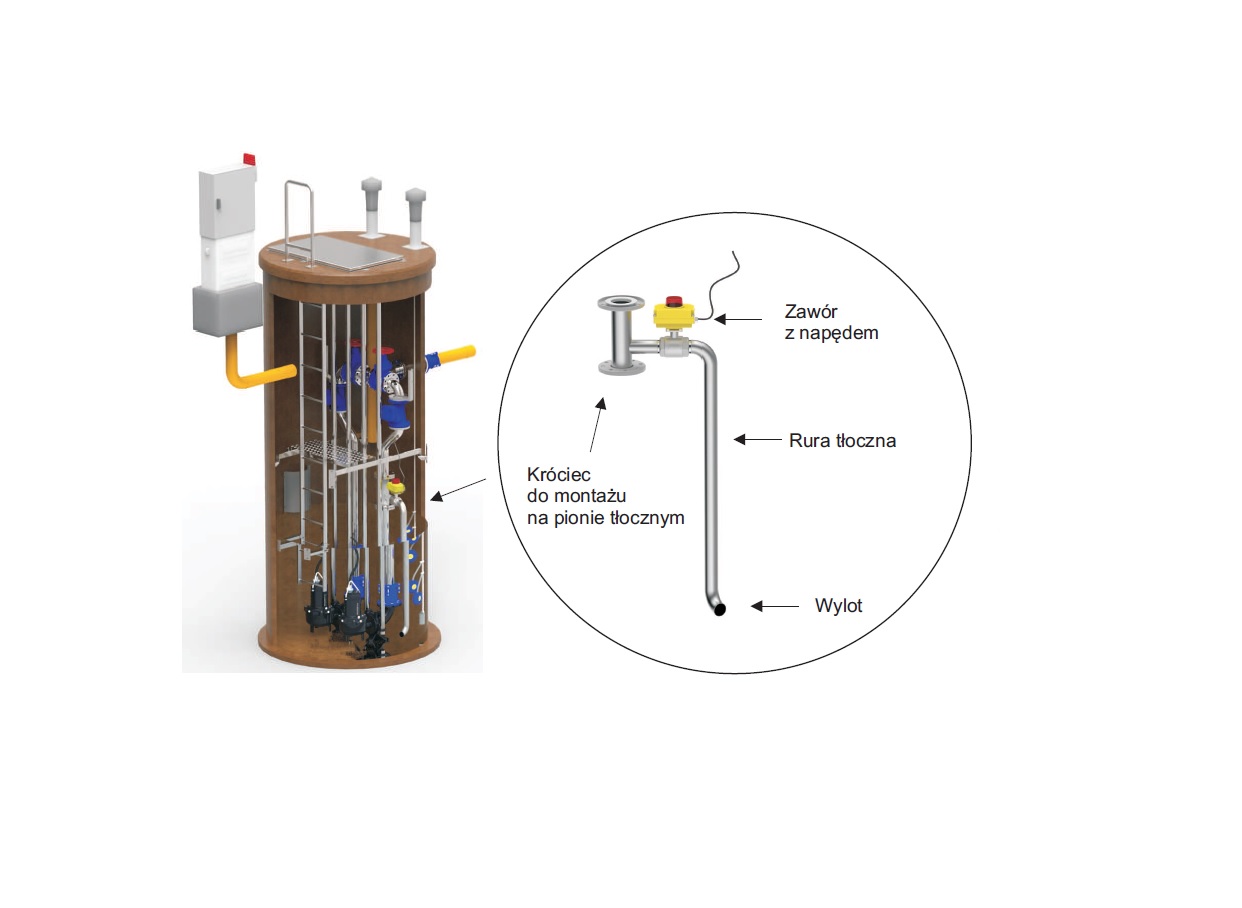

Flushing pumping station with MASP system

MASP – What is this and why we use it?

MASP SYSTEM is developed by METALCHEM-WARSZAWA S.A. Automatic Flushing System for pumping stations. It moves sediments from the bottom, breaks down the “scum” accumulating on the surface and facilitates self-cleaning of the pumping station. This system is an excellent alternative to expensive hydrodynamic flushing circuits mounted directly on the pumps.

Purpose

MASP SYSTEM – is intended for sewage pumping stations where there is a phenomenon of deposits of sediment, sand or fat deposits on the pumping station components. Forced movement of the medium in the pumping station tank causes the sludge to move, mix them with sewage and pump them out more easily. Thanks to this, pumping stations much less often require mechanical cleaning and intervention of a conservator. This has a significant impact on reducing the operating costs of the facility.

Advantages of MASP

- Moving the sediments and sand in the tank,

- Prevention of fat deposition on pumping station components,

- The system is independent of the manufacturer and type of pumps,

- Precisely adjustable switching frequency and rinsing time,

- Confirmation of operation with a control lamp in the switchboard,

- Free flow of medium through the system – no parts on which fibrous sewage contents can get caught and entangled (e.g. balls, flaps, screws, etc.),

- Valve drive insensitive to flooding or flooding,

- Adjustable depth and direction of the flushing pipe outlet.

Działanie

- Correctly installed MASP SYSTEM starts with one of the pumps in the pumping station.

- Part of the medium pumped by the pumps through the outlet, the solenoid valve and flushing pipe Dn50 (or larger) returns to the pumping station causing the medium to rotate in the tank. The properly selected diameter of the MASP forces circulation of the entire volume of the medium, preventing the build-up of sand, scum and grease in the tank.

- When the pumps wait for activation, the solenoid remains open, so it is important that it is located in front of the ball valve and does not empty the discharge pipeline to the pumping station.

- The valve closing time is about 17s and should be taken into account when setting the expected flushing time.

- After the set flushing time, the solenoid valve will close and all the turbulent medium will be directed through the pumps to the discharge pipeline.

- After switching off the pump and stopping the flow, the solenoid valve will be opened again and the system will wait for the next cycle.

How MASP works in practice

Installation MASP

- The T-piece with solenoid outlet and outlet pipe should be inserted below the ball valve on the discharge riser.

- The length and direction of the outlet of the flushing pipe should be selected individually to the size of the pumping station.

- Connect the valve control (RZS MASP) to the path of one of the pumps in the control box of the pumping station, and then set the MASP control to the frequency of starts (each or every nth cycle of pump activation).

- The standard solenoid valve cable has a length of 10m, it can be extended on request.

- The power connection must be made by qualified persons with due diligence so as not to damage the device or the power cord.

Available configurations MASP

Currently SYSTEM MASP span> is available with free passage from Dn50 to Dn100. The cost of the system includes: Control system (RZS MASP), solenoid valve with power and signal cable (10m each), a vertical tee mounted with outlet to the solenoid valve and a 2-3m flushing pipe.

Systems with a different length, construction method or larger diameter, e.g. Dn150, are priced individually.

WE INVITE YOU TO TEST OUR DEVICE

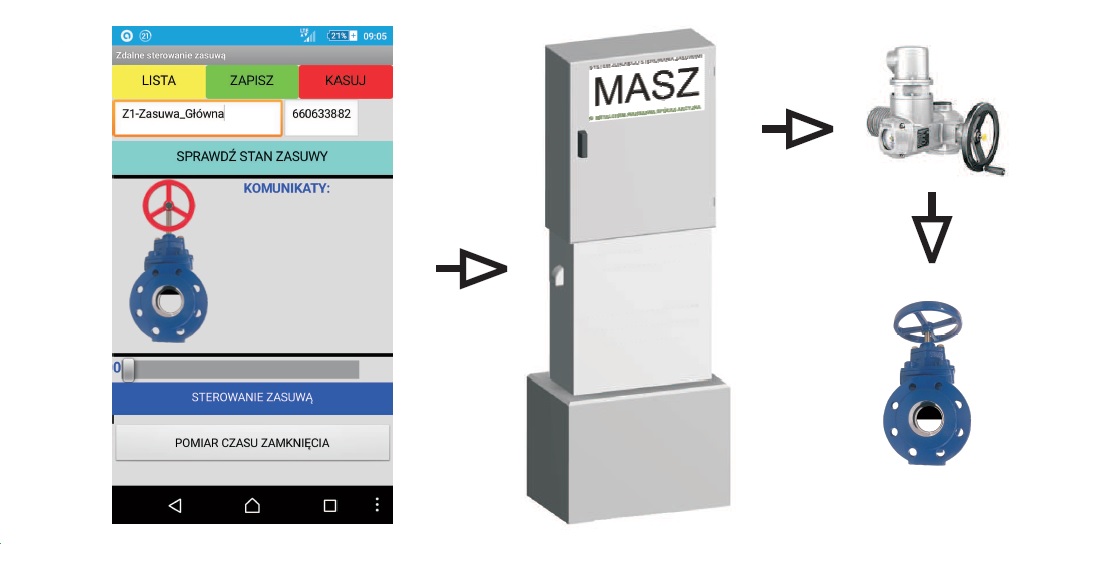

Remote control of MASZ gate valves

MASZ SYSTEM is a Mobile Shutter Control Application based on GSM data transmission technology. The set consists of an application for devices with the Android operating system and a power supply and control system. The system can be delivered as a complete product with gate valves (wedge, knife or gate valves) and their respective drives or be adapted to the existing conditions (gate valves or gate valves with drive).

Application -> Control -> Drive -> Gate valve

MASZ Purpose

MASZ SYSTEM is designed to control valves in remote locations where power is available and GSM signal, but it is impossible or unprofitable to lay cables for control signals, e.g.

- Sewage inflow to scattered pumping stations,

- Retention tanks, rainwater tanks or process water tanks *,

- Valves and valves on channels, pipelines and collectors

* Adjustment frequency depends on drive parameters

Advantages of the system MASZ

- Remote opening and closing,

- Possibility of setting intermediate states in the application, e.g. 20%, 47%, etc.,

- Low operating costs – SMS communication between any SIM cards,

- Two-way communication (feedback on the valve status – confirmation of the valve opening degree, type of failure),

- Possibility of any configuration of the set: different gate valves, different drives, etc.

Description of action MASZ

- Selection of the gate valve from the base (drop-down list),

- Checking the status of the valve (controller question) regarding percentage value of opening the gate valve or sending an error message (failure): power supply, motor overload, etc.,

- Setting the closing / opening value in the application through the slider,

- Confirmation and sending the command to the controller,

- Setting the preset value of opening or closing the shutter by the controller,

- Feedback confirming that the task has been completed.

General characteristics of the MASZ system

- Remote opening and closing,

- Possibility to set intermediate states of the valve using the slider located in the application, e.g. 20%, 47%, etc.,

- Automatic measurement of shutter opening / closing time,

- Checking the previous status of the valve – two-way SMS communication,

- System messages: closing percentage, power failure, motor breaker failure, motor thermal failure,

- Control of 400V or 230V drives as standard, optional control of 24V drives,

- Cooperation with drives from various manufacturers,

- The ability to support up to 100 valves from a single modem with a SIM card,

- List – creating your own valve database with descriptions and controller addresses,

- Alphabetical setting of entries in the gate valve database,

- The permissible number of control cycles per hour depends on drive parameters (other drives are used for continuous and quick adjustment of and dosing and others for occasional work),

- The standard cable between the control cabinet and the drive is 10m, other lengths are realized on customer’s request.

Possible configurations

- Application + Control box

- Application + Control box + Drive

- Application + Control box + Drive + Gate Valve

- Application + Control box + Drive + Gate Valve + Smartphone

Application – supports Android devices from version 2.3 onwards.

RZS – A power supply and control box with a modem GSM, each gate valve is assigned a separate controller, one modem GSM (1 SIM) can support up to 100 gate valve controllers.

Drive – the system works independently of the drive manufacturer (Auma, Centork, etc.)

Gate valve – knife, wedge and butterfly valves are most commonly used, but the system can also be adapted to ball valves including a quarter turn (closing / opening time decides).

Smartphone – an Android device that supports application.