The aeration waterjets are the most economical way to simultaneously oxygenate and mix wastewater and storm water in reservoirs and to aerate ponds, ditches, etc. Installing the aeration waterjets does not require additional construction and investment works. They can be used both in new investments and in existing tanks, where both circulation and aeration are insufficient and the bottom is covered with sediment. They also serve as replacement devices during periodic breaks in the operation of devices under repair or maintenance.

Compared to other aeration systems, the aeration waterjets have a number of beneficial features:

- High oxygen efficiency with relatively low energy consumption,

- Simultaneous mixing and oxygenation,

- Quiet and calm work in immersion,

- No possibility of aerosol formation,

- Elimination of emissions of pathogenic bacteria,

- Insensitive to work in freezing temperatures,

- Easy installation and expansion of the aeration system.

Characteristic features of aeration of wastewater by streamers

The presence of dissolved oxygen in the liquid is necessary to maintain the effective metabolism of bacterial cultures in biological purification processes. Aerating waterjets are ideal for this purpose, combining the advantages of an oxygenating and mixing device. By creating a strong stream of a mixture of liquids and air bubbles, the power waterjets create particularly favorable conditions for oxygen transfer and counteract sedimentation of sediments by reducing the BZT5 charge. The aeration technique using ejectors makes it possible to obtain high, effective oxygen transfer rates unattainable for other oxygenation methods. This is due to the occurrence of specific processes of overcoming the natural resistance of oxygen transfer at the interface of two phases: liquid and air. In the process of aeration with a jet pump, the liquid is transformed into a high-energy stream which mixes dynamically with the sucked air, creating water-air foam leaving the diffuser at high speed. The high velocity gradient occurring at the gas-liquid interface, combined with the high turbulence of the stream and the surrounding medium, create particularly favorable conditions for the passage of oxygen to the surrounding medium. for oxygen transfer due to continuous “renewal” of air bubble surfaces at the liquid and gas interface.

The principle of operation of aeration waterjets

The principle of operation of liquid-gas jets uses the phenomenon of pressure drop of the liquid stream associated with the increase in speed caused by the flow through the venturi in accordance with Bernoulli’s rule. Submersible pump METALCHEM-WARSZAWA S.A. cooperating with the jet set pumps the liquid from the process tank by pumping it through a special venturi as a result of which the speed of the stream increases and a vacuum zone is created, which sucks air from the environment into the suction chamber. In the further part of the aeration waterjets, dynamic mixing of liquid and air occurs, creating an air-water foam, which, in the diffuser, obtaining the pressure increase necessary to overcome the back pressure surrounding the liquid column, is ejected at high speed. The mixture of air and water bubbles, leaving the diffuser with high energy and speed, entails the surrounding liquid and, at the same time, due to the content of bubbles, the low specific density rises up to the surface creating particularly favorable conditions for oxygen transfer and effective mixing.

Selection of aeration waterjets for sewage

The size and type of the jet stream is selected depending on the hourly oxygen demand depending on the active depth of the tank and the required energy density in the active volume of the tank. With the increase in immersion depth of the waterjets diffuser, the path length of air bubbles in the liquid increases, increasing the efficiency of oxygen transfer. At the same time, as the depth increases, the back pressure increases, which reduces the amount of air supplied, reducing the effectiveness of oxygenation. The characteristics included in the catalog sheets represent the amount of oxygen supplied and the expected oxygen transfer under standard conditions (SOTR) for water at 20 ° C and zero oxygen saturation. Oxygen transfer diagrams are prepared for average operating conditions assuming an empirical coefficient of oxygen transfer efficiency of 5% for each meter of active reservoir depth. The efficiency of oxygen transfer to wastewater is lower than for clean water, therefore for process conditions it is recommended to take an average reduction factor of N = 0.80. The amount of oxygen transfer depends on many factors, among others temperature, concentration and age of the sludge, distribution of the waterjets, shape of the tank, degree of oxygen saturation, etc. and also from the intensity of mixing characterized generally by the energy density expressed as the ratio of the installed power of the waterjets to the active volume of the tank. Adequate mixing intensity in the entire active volume of the tank is particularly important in systems working with activated sludge, where complete mixing is necessary due to the need to eliminate bottom sediments. To obtain proper mixing in the whole volume, it is recommended that the energy density is not less than 25-40W / m³ for round or oval tanks and 35-60W / m³ for rectangular tanks, respectively. Higher values refer to higher sludge concentrations. In the event that the power of installed jets (y) resulting from the oxygen demand does not provide the above energy density indicators, it is recommended to use additional mechanical mixers.

How to install waterjets for aeration

For proper operation and obtaining the best oxygen transfer indicators, it is important to properly position and position the waterjets in the tank. There should be no obstacles in the path of the stream that would suppress its energy and the location of the waterjets should take into account the most favorable circulation of liquid in the tank.

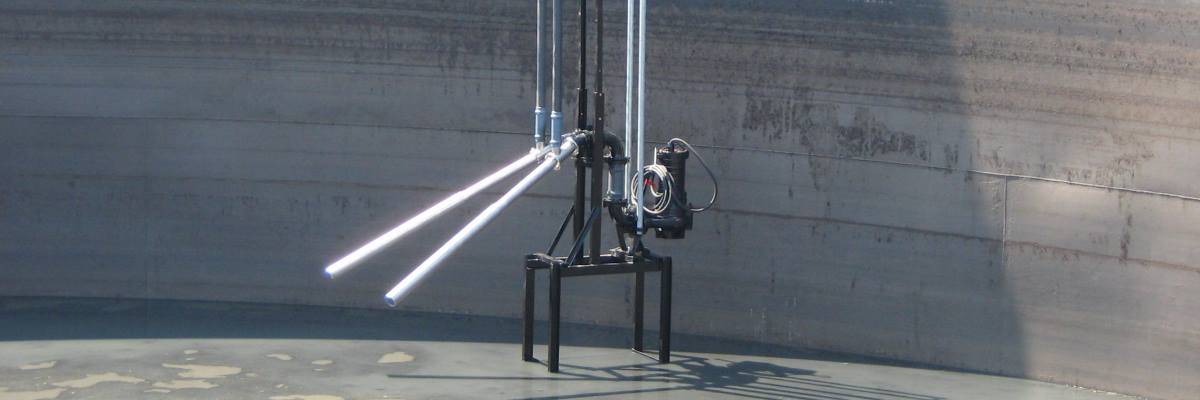

METALCHEM-WARSZAWA S.A. offers the entire series of aeration waterjet with various oxygenation capacities and execution variants adapted to various installation methods. We manufacture single-stream devices with the S1 -… designation with capacities from 1.5 to 3.0kW, double-stream devices with the S2 -… designation with capacities from 4.0 to 9.2kW and multi-stream devices with S3, SM and SR capacities from 15 , 0 to 18.5kW. The S2, S3 power tuneers have forked ejector pipes, so that there is no mutual damping and overlapping of streams. Main waterjets have one main supply pipe with side-oriented nozzles. Radial radiators have a centrally located pump and radially propagating ejector nozzles.

Types of waterjets for aeration

Installation versions:

S – standing,

Z – suspended,

PZ – attached-suspended,

ZN – hung-adjustable.

Waterjets type:

S1 – Single-stream devices:

- S1 – a aeration waterjet pump with a straight nozzle in the pumping axis of the pump (versions S, Z and PZ),

- S1P – a aeration waterjets with a straight nozzle raised in relation to the pump discharge axis (versions S and PZ),

- S1S – the aeration waterjets pump with an oblique nozzle raised in relation to the pump discharge axis (versions S and PZ).

,

S2 – Double-stream devices:

- S2P – the aeration waterjets with two straight nozzles (wersje S, PZ & ZN),

- S2S – the double aeration waterjets pump with an oblique nozzle (versions S, PZ & ZN).

S3 – the triple aeration waterjets:

- S3P – the triple aeration waterjets with straight nozzle (versions S, PZ & ZN),

- S3S – the triple aeration waterjets with a oblique nozzles (versions S, PZ & ZN).

SM – the Main aeration waterjets (one main preassure pipe and n* mixing streamers):

- SM4 – SM10 The aeration waterjets with n-streamers adjastable direction outlet.

SR – The radial aeration waterjets:

- SR3 – SR6 – n-nozzle radial waterjets with radiating outlets.

Special version waterjets:

We also make special waterjets tailored to the specific customer requirements. On request, we also manufacture waterjets control boxes according to the control algorithm provided by the customer. Freestanding waterjets of all installation versions are placed freely on the bottom of the tank without the need for any installation work except for connection to the electric power supply and control system, so they can be installed without having to empty the tank. Other installation versions for their installation require simple assembly works to anchor the supportive structures of the waterjets to the bottom or to the tank wall.